Do you really know how to choose the right wood panels for your

decoration or making furniture? It is really not an easy job for most of people.

Meanwhile, you might also need to take into consideration of other facts, such

as formaldehyde emission, price, working scenarios and so on. Well, let’s explore a bit and try to find out

the ways of choosing different kind of wood panels.

Generally, there are 5 main types of wood panels that we normally

use for either interior decoration or furniture industry.

MDF (Medium Density Firberboard)

This kind of board is compressed together with wood powder and glue. Thus, it is mainly use for shaping, carving. Meanwhile, it has a flat and smooth surface, making it easy for making gloss finish coating. But because of the structure, it is weak in intensity and easy to absorb water and expand. So, while we have to use it for the profile or shape, it’s better to have full coating covered to cut off from water.

Chipboard or Particle Board

This kind of board is compressed by small wood particles and

glue. It has better strength then MDF and structure is more stable for anti-twisting.

Meanwhile, it is also a cost-effective solution for cabinets. However, it does require

high precision sawing to avoid damage in edges. Thus, it is widely used for

melamine furniture industry.

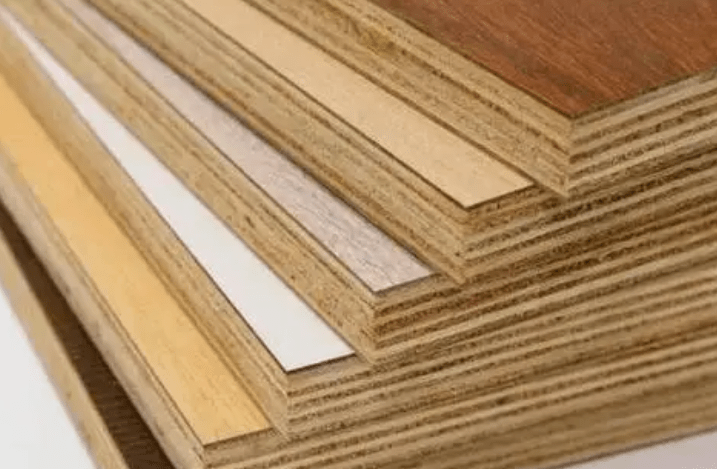

Plywood

Plywood is a kind of panel which is made of different solid wood sheets. Different layers of solid wood sheet are combined and compressed with glue like wafer biscuit. The main advantage is its strength in all directions and good moisture resistance. Thus, it is largely used in built-in furniture items as well as fixture.

Blockboard

The blockboard is a kind of panel that made of solid wood core & solid wood sheets on both top and bottom. As the solid wood core are laid out in same direction, it makes it weak in either horizontal or vertical way. Meanwhile, due to the combination of different solid wood core, it becomes weak in stability of expansion. Thus, it is not suggested to make the door with them directly.

Each wood panel has its advantages and weak points, we can flexibly choose them while we are making different items. Well, if you choose to make custom furniture with them, you can leave this to the factory who is professional on this.